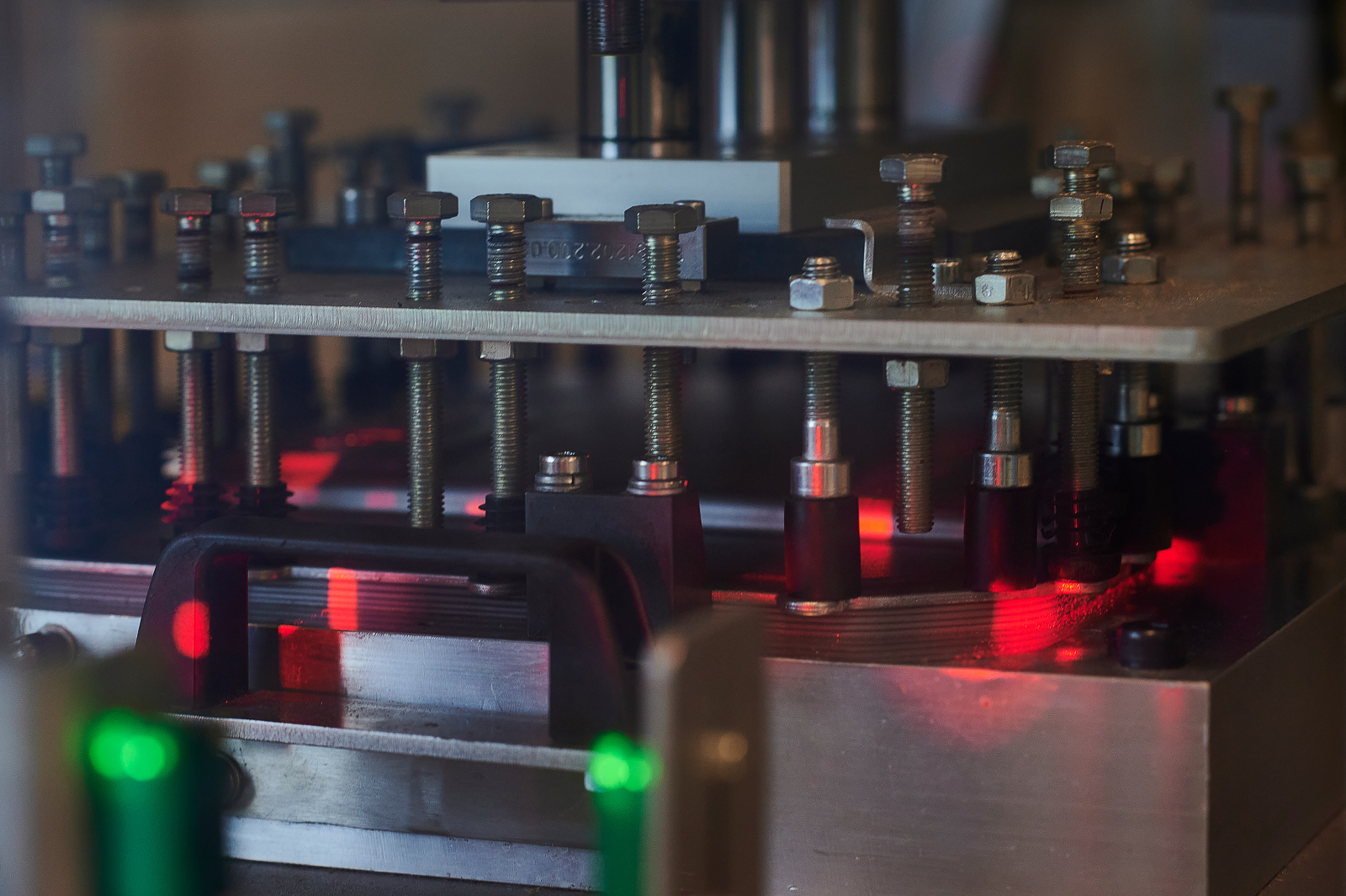

Impregnation and leakage control

In high-performance applications, even the smallest leak can compromise safety, efficiency, and lifetime value.

That’s why Alteams applies impregnation and leakage control methods to seal microscopic porosities in casted components. This ensures gas- and liquid-tight parts, reduces defect rates, and enhances long-term durability.

For industries like automotive, telecom, and energy, impregnation provides a cost-effective way to secure reliability without redesigning parts. By eliminating leakage risks at the source, we help our customers achieve consistent quality and confidence in every product.

Sustainable and Cost-Efficient Manufacturing

Impregnation not only prevents leakage—it also reduces waste and supports sustainable manufacturing:

- Lower scrap rates meaning fewer discarded components

- Extended component lifetime reducing replacements

- Reduced material waste with highly efficient resin utilization

- Optimized resource usage aligning with ESG objectives

This helps customers meet environmental standards while reducing total production cost.

Advanced X-Ray Inspection for Internal Defect Detection

Beyond impregnation and leakage control, X-ray inspection is an essential step in verifying the internal integrity of casted components.

This non-destructive testing method allows us to detect hidden defects—such as porosity clusters, cracks, shrinkage cavities, or structural inconsistencies—that cannot be seen from the outside.

By integrating X-ray testing into our quality assurance process, Alteams ensures:

- Complete visibility into internal structures

- Early detection of critical defects before assembly

- Higher reliability for safety-critical and high-precision applications

- Reduced scrap and rework through accurate quality feedback

X-ray inspection strengthens our end-to-end quality control, ensuring every component meets the performance and durability standards required in automotive, telecom, and energy applications.