Early Supplier Involvement (ESI)

Why Early Engagement Matters?

Early involvement allows us to identify challenges long before they impact cost, schedule, or performance. By collaborating at the concept and planning stage, we help your team refine design intent, confirm feasibility, and select optimal materials and processes.

This proactive approach not only shortens development cycles but also reduces potential redesigns and ensures your product is aligned with specifications, regulatory requirements, and cost targets from day one.

Common Challenges Without ESI

Many companies face costly setbacks when supplier input comes too late:

- Unexpected redesigns that delay launch

- Material selection issues affecting performance and cost

- Compliance gaps leading to regulatory risks

- Extended development cycles that increase overhead

By engaging suppliers early, these risks are minimized.

The Benefits of ESI

Working with suppliers from the start delivers measurable results:

- Faster time-to-market with fewer delays

- Reduced redesign costs and improved efficiency

- Optimized material and process selection for better performance

- Compliance and quality assurance from day one

Our ESI Process

At Alteams, we follow a structured, collaborative approach to ensure success:

- Concept Review – Aligning your design goals with feasibility and practicality.

- Material & Process Guidance – Advising on cost-effective, high-performance options.

- Prototype & Feedback – Identifying and resolving potential issues early.

- Production Planning – Ensuring smooth, efficient manufacturing that meets cost, quality, and regulatory goals.

Case Example: Early collaboration optimizes die casting production

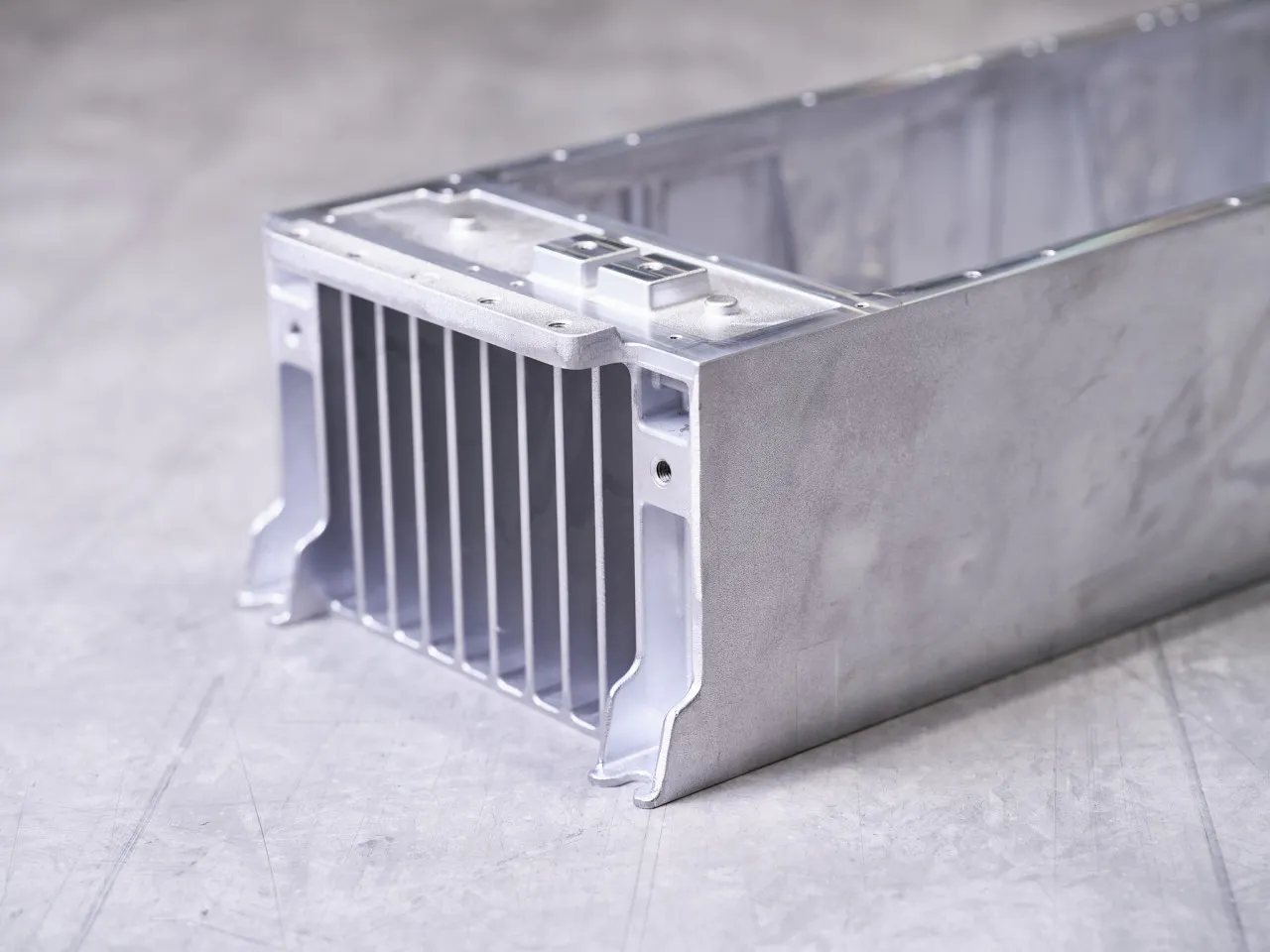

A German customer’s R&D team partnered with Alteams during the concept stage to enhance die casting manufacturability. By combining four separate components into a single complex die-cast housing, we helped improve structural integrity, enhance sealing performance (IP-rated), and eliminate assembly steps.

This early collaboration resulted in optimized cast part design, a 20% reduction in direct costs, and a smooth production transfer to our China manufacturing facility, with final delivery to Germany.

The next-generation product is now in full scale mass production, highlighting the impact of ESI and DFM optimization on efficiency, cost savings, and product quality.

Get started with Early Supplier Involvement today!

Don’t wait until design challenges delay your project or increase costs.

Partner with Alteams early and take advantage of our 80+ years of aluminium casting expertise to optimize your product from concept to production.